Round-bales are used throughout the horse industry as a means of providing forage to horses housed in poor pastures, dry lots, or during winter months1. The cost of hay fed in a round bale package is typically lower on a per ton basis than small square bales. The lower price coupled with the convenience of feeding are likely factors horse owners consider when feeding round bales.

However, some horse owners report excessive hay waste and horse weight gain from horses feeding on round bales. Waste from large round bales can occur during both storage and feeding. Dry matter storage losses of round bales can range from 2-40%, depending on type of forage, storage method, environment and storage length2. Hay waste was found to be higher for horses fed costal bermudgrass and alfalfa round bales without a feeder (38% and 31%, respectively) compared to utilizing a ring feeder (2% and 9%, respectively)1. When fed to beef cattle, different round-bale feeder designs resulted in different amounts of wasted hay3.

Several types of round bale feeders for use during horse feeding exist and claim to reduce or eliminate hay waste. However, little research has been done to characterize hay waste resulting from different round bale feeders when used in horse feeding. The objectives of this research were to determine hay waste, hay intake, horse weight change and economics of nine round-bale feeders and a no-feeder control during horse feeding.

How the Research was Conducted

In June of 2010, 50 round bales were baled from a pure stand of orchard grass and were stored until fed. Prior to storage, each round bale was individually weighed and analyzed.

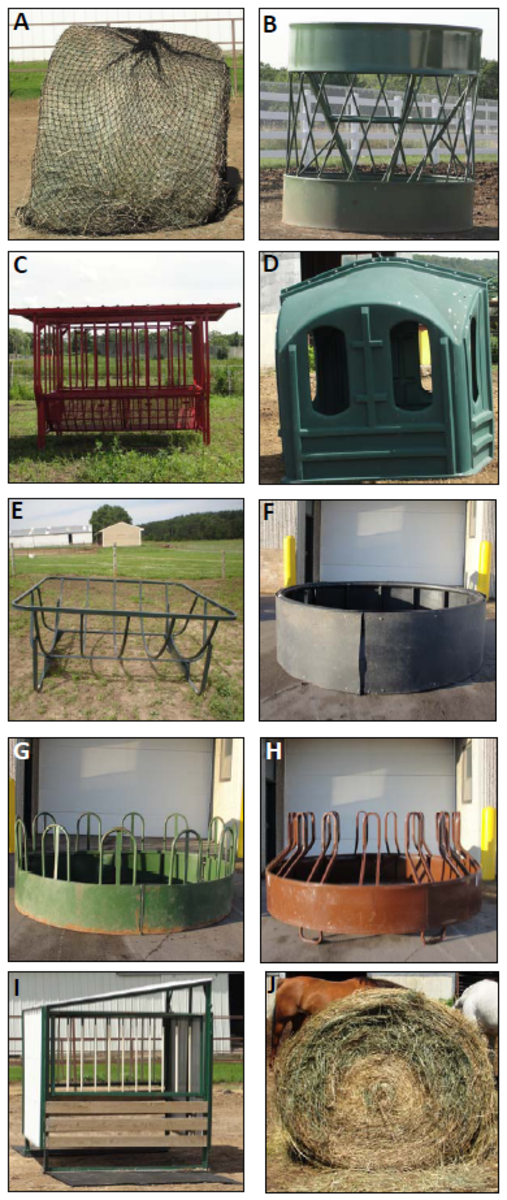

Nine round bale feeders, specifically manufactured and marketed to the horse industry, were tested, including (see above):

- A. Cinch Net ($147*; Cinch Chix LLC, North Branch, MN)

- B. Cone ($1,195*; Weldy Enterprises, Wakarusa, IN; model R7C)

- C. Covered Cradle ($3,200*; SM Iron Inc., Sanborn, MN)

- D. Hayhut ($650*; Hayhuts LLS, Deleon Spring, FL)

- E. Hay Sleigh ($425*; Smith Iron Works Inc., St. Francis, MN)

- F. Ring ($300*; R & C Livestock, Bethany, MO)

- G. Tombstone ($250*; Dura-Built, Eagan, MN)

- H. Tombstone Saver ($650*; HiQual, Victoria, British Columbia, Canada)

- I. Waste Less ($1,450*; JSI Innovations LLC, St. Croix Falls, WI)

- J. No-feeder control

* Prices quoted at time of research (July 2010), delivery not included, and prices are subject to change.

The Covered Cradle had collapsible side feeding panels that rested on the bale and compressed down as the bale was eaten. The Waste Less feeder also had collapsible side feeding panels, but panels were lowered by hand every day at 9:00 am and 9:00 pm to ensure horses had unlimited access to hay in the feeder.

Twenty-five mature Quarter Horse and Thoroughbred geldings and mares from the UW- River Falls campus herd were used to form five groups of five horses. Groups were of similar age, initial weight, breed and gender. Each feeder was placed on the ground in an outdoor dirt paddock. The groups of horses fed in rotation for four days, and every fourth day, groups were rotated to a different paddock which housed one feeder and a new round bale. In all, 25 horses fed off each feeder for 20 consecutive days. Horses had unlimited access to shelter, water, a trace mineralized salt block and hay in the feeder. Horse weight was individually measured each time the groups entered and exited a paddock.

Hay that fell onto the ground surrounding the feeder was considered waste and was collected daily starting at 9:00 a.m. Care was taken to avoid collection of manure and dirt. All waste was dried to approximately 15% moisture. Hay remaining in the feeder at the end of the four day period was removed. Hay disappearance was calculated as the amount of hay delivered to each paddock, less the remaining amount of hay in the feeder at the end of the four-day period. Percent waste was calculated as the amount of hay waste divided by hay disappearance. Dry Matter intake (DMI) was estimated as the difference between hay disappearance and hay waste and was expressed as percent body weight (BW) by dividing hay intake by average horse weight upon entering the paddock. Herd weight change was the difference between the initial herd weight minus the final herd weight after four days. Months for waste reduction to pay back feeder cost (payback) was calculated using hay valued at $100/ton and based on mean waste from the no-feeder control.

Experimental procedures were conducted according to those approved by U of M and UW-River Falls Committees on Animal Use and Care.

RESULTS AND DISCUSSION

Horse Safety

No injuries were observed from any feeder types during the data collection period. However, cosmetic rub marks along the sides of faces were observed on many horses feeding out of the Waste Less feeder. After two day of feeding off the Cinch Net, the round bale collapsed down and horses were able to stand and defecate on the remaining hay. We recommend using the Cinch Net in conjunction with another feeder to avoid horse access as the round bale collapses down. The manufacture also recommends that horses should not be shod when feeding from the Cinch Net.

Weather

During the study, the average maximum daily temperature was 81 degrees F with a total of 6″ of rainfall; which likely did not affect hay intake or waste. The daily collection and drying of hay further limited the effect of rainfall on hay waste.

Hay Waste

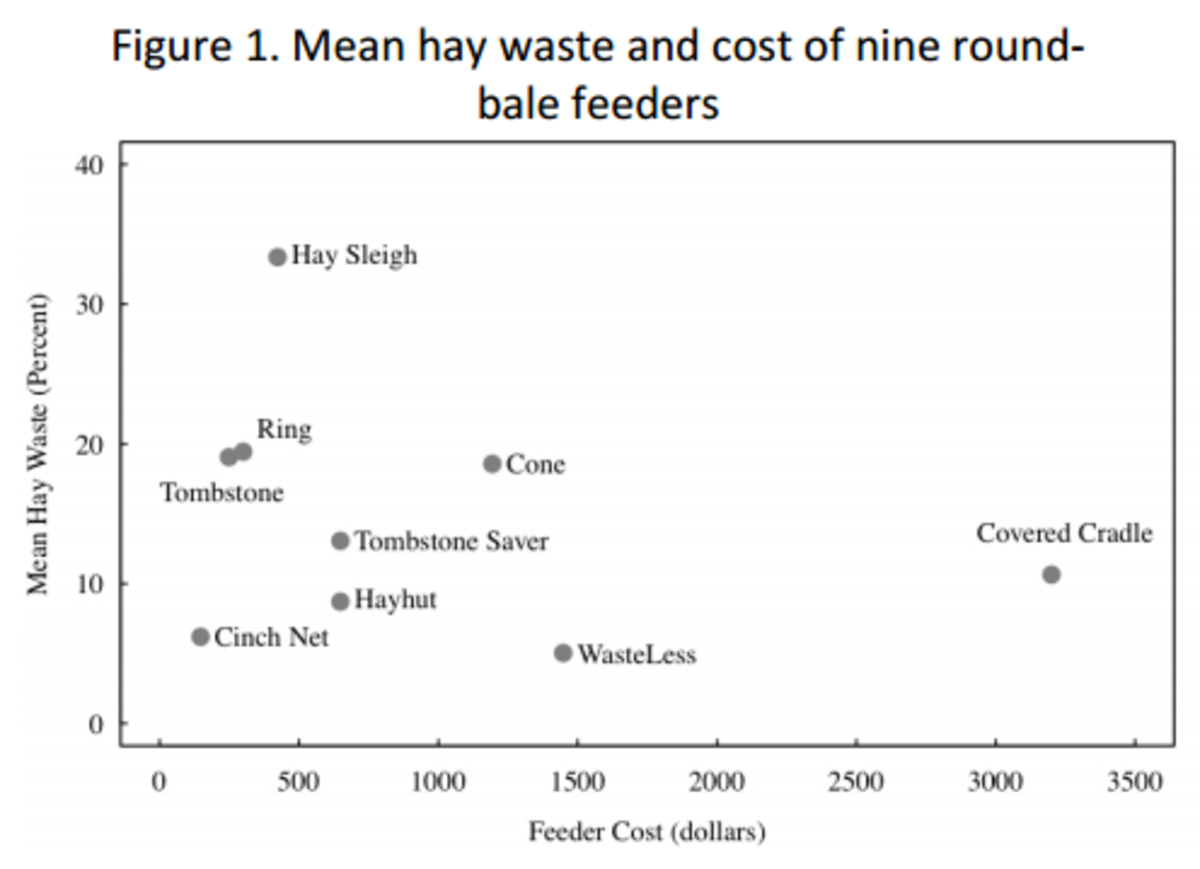

Hay waste differed between round bale feeder designs. Mean percent waste was, in increasing order: Waste Less, 5%; Cinch Net, 6%; Hayhut, 9%; Covered Cradle, 11%; Tombstone Saver, 13%; Tombstone, Cone and Ring, 19%; Hay Sleigh, 33%; and no-feeder control, 57% (Table 1). All feeders reduced waste compared to the no-feeder control.

Feeders that were more restrictive (i.e., Waste Less, Cinch Net, Hayhut and Covered Cradle) resulted in less hay waste. With the exception of the Hayhut, these feeders did not allow horses to immerse their heads into the bale, and horses were frequently observed pulling small mouthfuls from the bale, eating the hay, and wasting less. Feeders that provided greater access to hay (i.e., Hay Sleigh, Ring and Tombstone) resulted in more waste. Horses were frequently observed immersing their entire head into the bale, pulling hay out of the feeder, and dropping it on the ground.

There were no significant differences in hay waste between the circular feeders: Tombstone Saver, Tombstone, Cone and Ring. Distinct burrowing holes where observed from horses feeding on round bales inside the Hayhut, Tombstone, Ring and Tombstone Saver.

Hay Quality, Horse Intake, and Weight Changes

Round bale forage quality means were 10% crude protein (CP); 0.90 Mcal/lb Equine Digestible Energy (DE); 0.33 Calcium (Ca) and 0.32 Phosphorous (P). The orchard grass hay met or exceeded the horses’ nutritional requirements for DE, CP, Ca and P at the 2.0% feed intake for mature, idle horses4.

Feeder design did not affect horse hay intake. All feeders resulted in 2.0 to 2.4% DMI per horse BW (Table 1). The no-feeder control resulted in less DMI (1.3% BW) when compared to all other feeders.

Herd weight change was not different among feeder types (Table 1). However, the no-feeder control resulted in herd weight loss compared to six of the feeders. The reduced DMI and herd weight loss resulting from the no-feeder control is likely due to greater hay spoilage from horse defecation, urination and trampling of hay. Hay intake of 2.0-2.4% BW resulted in excessive DE intake of 19% to 42%, respectively, which accounted for herd weight gain with six of the feeders. Excessive weight gain is problematic and has been linked to several equine health disorders. At 1.3% of BW intake, DE requirements were not met for the no-feeder control, accounting for the herd weight loss. However, CP, Ca and P requirements were still met4.

Table 1. Hay waste, hay intake, weight change, and payback of nine round-bale feeders and a control

Within a column, means without a common superscript letter differ (P < 0.05).

Economics

Feeder design affected payback. The Cinch Net paid for itself in less than 1 month; Tombstone and Ring, 2 months; Hayhut and Tombstone Saver, 4 months; Hay Sleigh, 5 months; Waste Less, 8 months; Cone, 9 months; and Covered Cradle, 19 months (Table 1 and Figure 1). A low amount of hay waste and affordable price resulted in the quickest payback time for the Cinch Net. Although the Waste Less feeder resulted in the least amount of waste, the higher price ($1,450) resulted in a longer payback period of 8 months. Although the circular feeders (Cone, Ring, Tombstone and Tombstone Saver) resulted in similar hay waste, the price difference between feeders ($250 to $1,195) resulted in a faster payback (2 months) for the more affordable Ring and Tombstone feeders. Although the Cinch Net paid for itself in the shortest amount of time, the net material is guaranteed to last for 3 years, while all other feeders claim to last indefinitely. Feeder longevity was not measured in this study, nor accounted for in the payback. Selecting feeders in the lower left hand side of Figure 1 will result in more efficient and affordable feeders.

Conclusions

Round bale feeder design affected hay waste and economics, but not safety, hay intake or herd weight change during horse feeding. The use of a round-bale feeder, regardless of design, is necessary to avoid the 57% mean hay waste, reduced hay intake, and horse weight loss observed when not utilizing a feeder. The excessive hay waste observed with the no-feeder control will also likely contribute to insect breeding areas, mud, and additional manure removal costs. Economics were impacted by both waste efficiency and feeder purchase price, however, all round-bale feeders repaid their cost within 20 months. Months to payback feeder cost is cut in half with hay valued at $200/ton. This information is useful when purchasing round-bale feeders and determining hay needs.

Funding and Acknowledgements

This project was funded by a grant from the MN Horse Council, manufacturer fees, and the U of M Undergraduate Research Opportunity program. We acknowledge the assistance and cooperation of UW-River Falls.

Literature Cited

- McMillan, M.L., Wilson, K.R., Golden, W.C. and Rakowitz, L.A. 2010. Influence of Hay Ring Presence on Waste in Horses Fed Hay. The Texas Journal of Agriculture and Natural Resources. 22:82-86.

- Harrigan, T. M., and C. A. Rotz. 1994. Net, plastic, and twine wrapped large round bale storage loss. Appl. Eng. Agric. 10:188-194.

- Buskirk, D., Zanella, A., Harrigan, T., Van Lente, J., Gnagey, L., and Kaercher, M. 2003. Large round-bale feeder design affects hay utilization and beef cow behavior. J. Animal Science. 81: 109-115.

- National Research Council. 2007. Nutrient Requirements of Horses. Sixth Revised Edition.

Manuscript Citation: Martinson, K., Wilson, J., Cleary, K., Lazarus, W., Thomas, W., and Hathaway, M. 2011. Round-bale feeder design affects hay waste and economics during horse feeding. J. Anim Sci. http://jas.fass.org/cgi/content/abstract/jas.2011-4087v1

Reviewers: Harlan Anderson, DVM, Idle Acres; Robert Coleman, PhD, University of Kentucky; and David Freeman, PhD, Oklahoma State University.

Photo Credits: K. Martinson and K. Cleary, University of Minnesota

Disclaimers: Mention of trade names in this fact sheet is solely to provide specific information and does not imply recommendation or endorsement by the University of Minnesota, nor does it imply approval to the exclusion of other products.